Post Date: December 18, 2020

Reliable Coding of Face Masks

Filtration Group is an expert for non-woven fabric and filter solutions. Manufacturing protective face masks was an almost obvious choice when the need for them grew dramatically due to the COVID-19 pandemic. The company now produces 30,000 masks per week in Germany. Their filter medium was slightly adapted to this specific purpose and provides high-level protection from droplet infections. The FG DropSafe™ masks for personal use consist to 100% of polyester fibres. During production, rolls of non-woven fabric are placed into special machinery, emerging as masks after an automated process.

Markoprint inkjet printers – easy to integrate

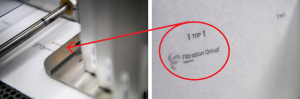

A Markoprint® thermal-inkjet printer applies text, codes and logos on the non-woven fabric before it turns into masks. The Integra Quadro controller operates up to four printheads, which can print independently or synced as a group. That means it is possible to print various lines and positions or stack them to create larger prints.

Filtration Group uses thermal inkjet cartridges with a maximum print width of 12.5 mm. The three cascaded printheads are mounted at a slight offset, which enables the 37.5 mm print width on the non-woven fabric. The inkjet printer was installed so that the material traverses the machine horizontally, while the printheads above automatically mark the fabric at set intervals.

Certified ink for secure printing

All Markoprint inkjet printers work with iDesign software. The proprietary Markoprint software processes data at very fast speeds. The masks are printed with the Filtration Group logo and plain-text information, including the manufacturing date, a ‘Made-in-Germany’ label and instructions for use. Print layouts could also contain barcodes or two-dimensional data-matrix or QR codes. The intuitive iDesign software makes it easy to create and manage various print layouts in addition to letting users start, pause and stop print jobs. iDesign also displays operating statuses, ink levels, and print data for an unlimited number of connected Markoprint systems. An ink-usage calculator helps users estimate and save consumables.

Wide range of industrial marking options

Markoprint inkjet printers are compatible with various printing technologies (HP, Xaar, Seiko, Funai, Trident) to provide an array of marking options regarding print widths and maximum resolutions. A quad printhead printing system, such as used by Filtration Group but with different cartridges, would allow for large-character coding with a maximum print width of 400 mm. As every ink cartridge comes with its own printhead, each new cartridge is basically a brand-new printhead. As a result, printing quality stays consistent, while cleaning and maintenance needs are low.

How can we help you?

If you are searching for industrial labeling and coding solutions to improve your performance in production and logistics processes, we are looking forward to hearing from you!