Post Date: April 16, 2024

Make Your Mark on Packaging – with Markoprint

Demand better print results and increased uptime!

Markoprint industrial inkjet printers distinguish themselves from other coding systems through exceptionally high efficiency and innovative features. With our wide range of printing systems and technologies, Markoprint coding solutions meet every system environment and customer requirement. We offer the right system for many applications in food, beverage, automotive, consumer goods, pharmaceutical and more.

Our developments result in first-class, highly complex solutions that are easy to use. With Markoprint you get durability, sustainability and many years of usage! When you consider the quality of Markoprint products versus other brands, there’s really no comparison.

Flat or Formed Substrates

Markoprint coders enable customers to print on flat or formed packaging, and always at fast speeds. The key to success is having a material handling system that consistently presents the packaging substrates within 1 to 5 mm of the printhead. Flat packaging such as cartons, sleeves and pouches can run at the highest speeds when a Markoprint coder is integrated on a friction feeder.

In situations where the packaging must be coded after the package is formed, a Markoprint coder can be mounted to print either vertically down or horizontally onto the substrate. While speeds may be slower when printing on formed packages, you still achieve high-quality codes including alphanumeric text, barcodes and graphics.

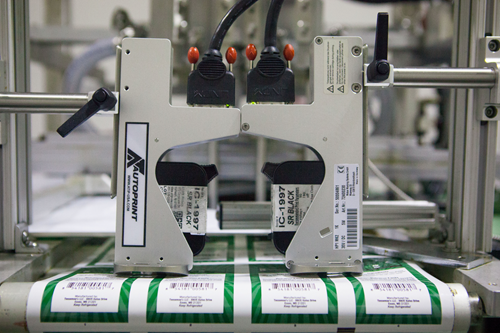

Integration on Packaging Machinery

The versatility of Markoprint allows for integration on a wide range of packaging equipment. Common installations of Markoprint include conveyors, feeders, sealers, egg packers, labelers, and Form Fill Seal machines. To fit into tight spaces, Markoprint was designed with a slim profile. Our coders are regularly used to replace old, antiquated systems such as hot stamp, embossers, thermal transfer, and continuous inkjet. The 2 rows of print nozzles allow one Markoprint coder to print on two adjacent products or print areas.

The versatility of Markoprint allows for integration on a wide range of packaging equipment. Common installations of Markoprint include conveyors, feeders, sealers, egg packers, labelers, and Form Fill Seal machines. To fit into tight spaces, Markoprint was designed with a slim profile. Our coders are regularly used to replace old, antiquated systems such as hot stamp, embossers, thermal transfer, and continuous inkjet. The 2 rows of print nozzles allow one Markoprint coder to print on two adjacent products or print areas.

Inks for Virtually Any Substrate

In 2014 HP launched the first solvent ink cartridge, and ever since the portfolio of available inks has increased greatly.

- Aqueous inks: used for porous packaging materials including paper, cardboard, pulp cartons, and lumber

- Solvent inks: used for non-porous packaging materials including flexible film, rigid plastic, foil / metal, PVC, and substrates with glossy overcoats

- UV-LED inks: used for plastic and glass materials that require alcohol resistance

- UV Invisible inks: used for anti-counterfeit applications; the ink is invisible until fluoresced with a UV light source

To speak with someone from AT Information Products about your specific application, call (201) 529-0202 or send an email to [email protected].