Post Date: May 9, 2019

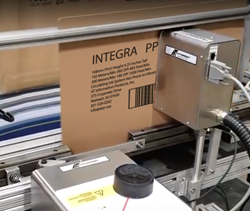

Integra PP108 – a revolutionary, standalone print system

The Integra PP108 is a revolutionary, standalone print system intended for large print areas on corrugate and other porous substrates. It leverages the Seiko print head and a circulating print system. The seamless print area is 108mm, or 4.25-inches tall. See why more and more manufacturers are switching to Integra PP108 for their large character case coding requirements.

-

- Installation Height – No need to worry about proper ink system placement. Integra PP108 can print horizontally or vertically down with no change to the ink system placement.

- Start Up Time – Integra PP108 starts up in less than one minute. There’s no priming, no heating up, and no purging necessary.

- Production Speed – Integra PP108 can keep up with the speed of production. It runs 492 FPM at 360×360 DPI, and 984 FPM at 180×360 DPI.

- Print Resolution – Integra PP108 has much higher resolution than Trident or Xaar. The print resolution is is completely controllable in the software which yields better ink cost control.

- Vibration – Because of the recirculating ink system, vibration does not effect the Integra PP108. The system is shock resistance and is not prone to deprime.

- Maintenance – The combination of the recirculating ink system and the SEIKO print engine makes Integra PP108 extremely robust. Missing channels are much less of an issue, and in most cases a simple wipe will recover the printhead.

To see Integra PP108 in action see https://www.youtube.com, or call us at (201) 529-0202 to arrange a demonstration.