Post Date: February 11, 2021

Flow Wrap Operations Deploy MARKOPRINT® for Coding of Products

Flow wrapping is essentially a horizontal process in which the products of any shape or size can be wrapped in plastic films or foils consisting of clear or printed polypropylene films. The end-packaging is considered safe, secure, and flexible, with minimal product shifts in the package. Superior to overwrapping in many ways, flow-wrapping is extensively used for packaging trillions of products such as food items, cosmetics, electronic components, and machinery.

The BENEFITS of flow wrapping include

- Extended shelf life.

- Air-tight packaging for complete moisture and air barrier.

- Tolerance for varying size of product.

- Easy setup and changeover for multiple sizes.

- Speeds up to 160 packages per minute.

- Easily integrates with Markoprint® to code packaging

With the installation of a Markoprint® industrial coder, flow wrappers can add fixed or variable data without slowing down the line. Typically these inkjet coders are used to print lot/batch, expiration date, barcodes, and small graphics. Markoprint can handle varying size codes on multiple substrates used in flow wrapping: aluminum, aluminum foil laminate, BOPP, multi-layer laminate and paper.

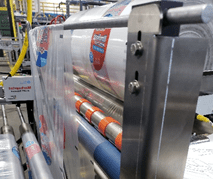

See Markoprint® in action for plastic foil on a flow pack machine using X1Jet from AT Information Products. This application uses the HP 2580 Black Solvent ink to mark the plastic packaging for strawberries and other fresh produce.