Post Date: July 16, 2021

Coding of Nutrition Panels in One Pass

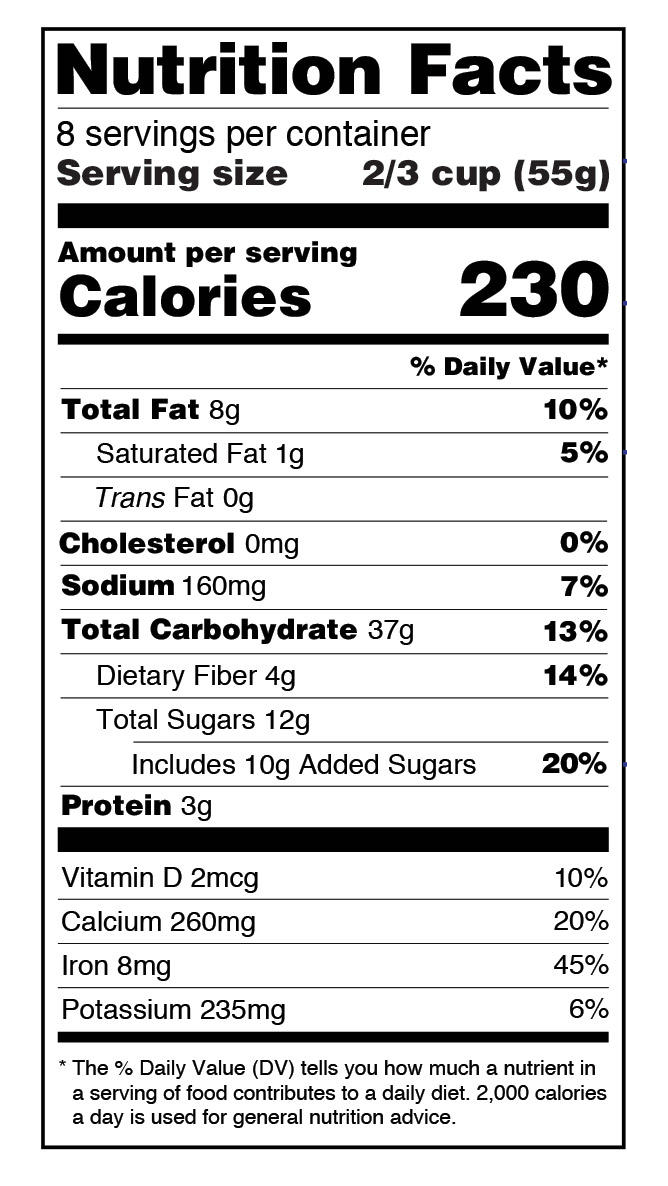

Food manufacturers must print the nutrition panel on their products and packaging. One trend is to use a large, high-resolution coder that can print the entire block of data in one pass with a large character system. If the manufacturer can reduce the need for pre-printed packaging, then they achieve greater flexibility and lower box inventory.

Food manufacturers must print the nutrition panel on their products and packaging. One trend is to use a large, high-resolution coder that can print the entire block of data in one pass with a large character system. If the manufacturer can reduce the need for pre-printed packaging, then they achieve greater flexibility and lower box inventory.

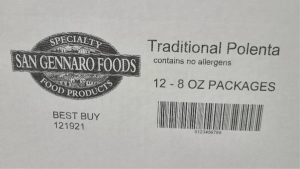

The Markoprint Integra PP108 4.25-inch coder is growing its footprint in food packaging. The high-speed, high-resolution coder is well suited for printing on porous materials including corrugate, paper bags, lumber and more.

Other piezoelectric case coders have been used with limited success. The print quality of barcodes has been the downfall for legacy case coders. With Integra PP108, printing at 360 dpi is more than enough to deliver barcodes that grade as a solid A.

In addition to barcodes, Integra PP108 is capable of printing logos and graphics that nobody thought possible with piezoelectric coders. Another advantage is its ability to handle vibration. Since the Integra PP108 has a pressurized, continuous flow of ink, the printer overcomes vibration and delivers a great code virtually every time.

In addition to barcodes, Integra PP108 is capable of printing logos and graphics that nobody thought possible with piezoelectric coders. Another advantage is its ability to handle vibration. Since the Integra PP108 has a pressurized, continuous flow of ink, the printer overcomes vibration and delivers a great code virtually every time.

Finally, with Integra PP108 comes the ability to print in two spot colors simultaneously. In addition to black ink, Integra PP108 prints high quality characters and codes in red, blue or green. This allows the manufacturer to highlight certain information on the packaging such as dates, instructions, and warning symbols.

Contact AT Information Products to learn more. Call (201) 529-0202 x125 or send a message to [email protected]