Post Date: May 19, 2021

Codes for Spuds, despite potato dust

Potatoes are the world’s fourth most important food crop after rice, wheat, and maize. They are a vital food-security crop considering its high yield and great nutritive value.

Potatoes are the world’s fourth most important food crop after rice, wheat, and maize. They are a vital food-security crop considering its high yield and great nutritive value.

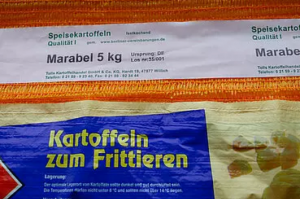

One of the large producers of potatoes is Tolls Kartoffeln, who’s involvement in spuds goes back to the 1890’s. In its modern production facilities, Tolls packages various size bags of potatoes ranging from 1 kg household bags to bags weighing 25 kg.

According to Tolls, every individual packaging unit is labeled with the type, weight and batch information. The potato bagging plant sews a plastic tag with such detail into the seam directly. “We have specific instructions for our labeling, depending on production. Despite the dusty environment, the plastic tags must be marked clearly legible and abrasion-resistant,” explains the Tolls production team.

Tolls Potatoes uses the X2JET plus Touch printer by Markoprint. The inkjet printer has convinced the company: “Apart from impressive print results, the easy operation was instrumental to deciding on the X2JET plus Touch.” Tolls is at present only printing text to enable product tracking such as name, date and batch data on its tags. It would also be possible to print various logos and barcodes, however.

Tolls Potatoes uses the X2JET plus Touch printer by Markoprint. The inkjet printer has convinced the company: “Apart from impressive print results, the easy operation was instrumental to deciding on the X2JET plus Touch.” Tolls is at present only printing text to enable product tracking such as name, date and batch data on its tags. It would also be possible to print various logos and barcodes, however.

Top resolution for perfect print images

The printing system includes a controller and two independently controlled print heads. Tolls uses Hewlett Packard ink cartridges capable of printing resolutions up to 600 dpi. Ink cartridges and print heads come as a unit. You therefore receive a brand new print head when you replace the cartridge for a new one. To protect the jets from dust and drying out, the cartridge may be sealed when not in use, manually or fully automatically.

At Tolls, the print heads are independently deployed at two different production lines. The company admits that its technicians had occasion in the past to build their own print head bracket after a production line needed re-adjustment: “We suddenly needed to print the data onto the plastic label upside down at our clip lock. We therefore simply relocated the print head – this worked with no problem at all!”

At Tolls, the print heads are independently deployed at two different production lines. The company admits that its technicians had occasion in the past to build their own print head bracket after a production line needed re-adjustment: “We suddenly needed to print the data onto the plastic label upside down at our clip lock. We therefore simply relocated the print head – this worked with no problem at all!”

Thermal inkjet sticks even to plastic

Markoprint equipment with Hewlett Packard ink is highly capable. A thermal pulse ejects ink from a print head jet. This method originally used water-based inks, which adhered well to absorbent surfaces such as paper and cardboard. Markoprint then developed a fast-drying type of ink that also sticks to “non-absorbent” surfaces such as plastics. The Markoprint printers at Tolls are therefore able to print on PE foil fast and abrasion resistant.

Production management was taken in not only by the X2JET plus Touch print heads, but also by the user-friendly controller: since a touch screen will allow all the relevant parameters to be set fast and conveniently, using simple and intuitive symbols. The software idesign is included in the printer delivery. Tolls staff use this program to create their print layouts on a PC before transferring the code to the controller via USB stick.

A printing system linked to all networks PCs via Ethernet

The printer may alternatively be linked to all network PCs via Ethernet. Not only will this connection simplify data transfer, but it also allows all print functions to be controlled from the PC directly: Operators can identify if the print head is busy printing a text and if the ink cartridge will soon require replacement. Should the printer be directly linked to an ERP database, the system is able to use the item number to extract the required print information from the database and transfer this to the print layout.

To see how Markoprint looks when printing your codes – alphanumeric, barcodes & graphics – contact AT Information Products by calling (201) 529-0202. Or send an email inquiry to [email protected]