Post Date: June 1, 2022

“A” GRADE IN LUMBER CODING

The United States is the leading producer and consumer of wood products in the world. The majority of wood is used to build 1 million new single-family homes every year or to repair and remodel existing houses. But with the high demand for lumber comes industry requirements in coding.

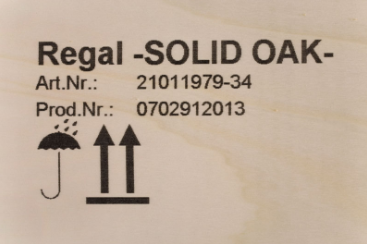

Markoprint technology has made the coding of wood more efficient than ever. From raw lumber in construction, to coated furniture, to varnished flooring and more, the system of codes and standards for wood materials ensures quality of these products is well established and reliable. Consider these various coding applications:

- Dimensions and specs

- Structural ratings

- Stress grade test results

- Timber species identification

- Date, time, shift, and batch codes

- Product codes

- Company branding and logo

- Barcodes and 2D data codes

- Association trademarks

Markoprint offers two print technologies that are well suited for wood coding.

For large print areas, Integra PP108 features a 4.25-inch tall printhead that codes at up to 300 dpi and is vibration resistant, which equates to superb print quality on wood. High speeds are also supported as Integra PP108 runs at up to 492 fpm when printing at 300 dpi.

For smaller print areas, the Markoprint X1Jet coder leverages HP inkjet technology and is a low-cost option. Our portfolio of porous inks delivers high-quality, high-contrast codes on a wide range of wood products. The inks also perform well in terms of UV sun light resistance.

To test Markoprint technology on your wood products, contact AT Information Products at (201) 529-0202 or send a message to [email protected].