Post Date: January 31, 2015

Avoid Spoil with Foil

There’s no disputing that aluminium foil usage in packaging applications is on the rise. This trend is no surprise to engineers who understand the many advantages of foil. The raw materials (90%+aluminum) are plentiful, inexpensive, durable, non-toxic, and greaseproof. Most importantly, aluminum foil is impermeable to water vapor and gases which leads to extended shelf life for food & beverage products.

The most common packaging applications are the following: (1) semi rigid foil containers, (2) caps, cap liners and packaging enclosures, (3) composite cans and canisters, and (4) flexible packaging.

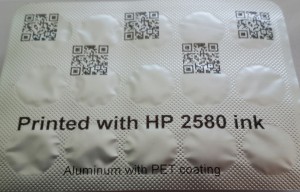

To keep pace with the increased usage of aluminum foil in packaging, coding technology advancements were required. For applications using coated foil substrates several new ink products now exist leveraging Hewlett Packard’s thermal inkjet. HP 2580 Black Solvent Ink, for example, provides durable coding and marking and delivers fast dry time without heat assistance. It works well on many challenging substrates including blister foil packs, flexible film, PVC, metals, UV coatings and more.

Two additional inks with similar effectiveness as HP 2580 on foil packaging products are: IQ990 from General Ink, and Sirius Black from Collins Ink. Both feature excellent print quality, fast dry time, and longer decap times which ultimately boost productivity.

Contact AT Information Products to learn more about the use of HP thermal inkjet for printing on aluminum foil applications in the packaging industry.