The Challenge of Pallet Marking in Harsh Industrial Environments

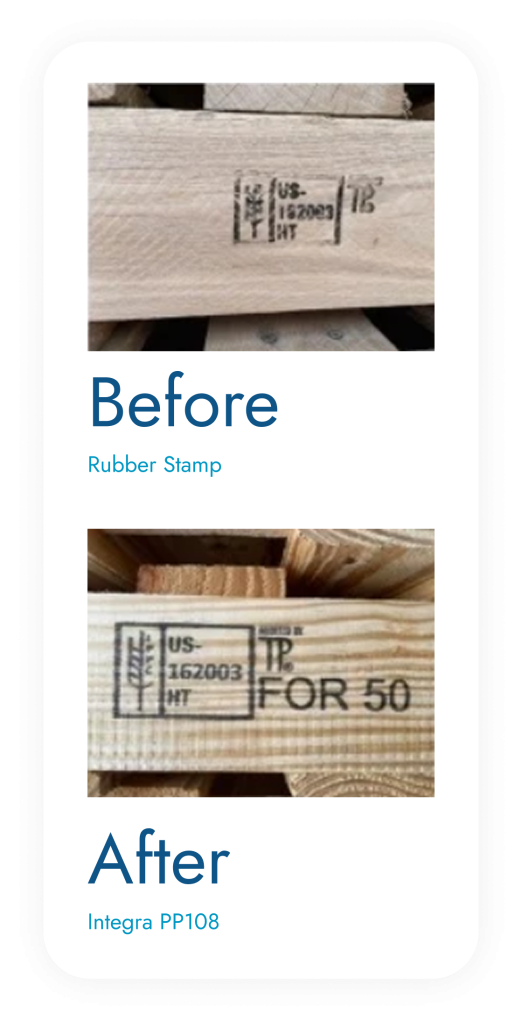

Quint-C Pallet Company, based in Limestone, TN, faced growing inefficiencies in their pallet marking operations. Relying on outdated manual stamping and heat branding, their process was slow, labor-intensive, and prone to errors—resulting in:

- High labor costs

- Inconsistent pallet markings

- Frequent production delays

The tough industrial environment—full of vibrations, sawdust, and splinters—further complicated marking consistency. These manual methods couldn’t deliver the reliability or speed needed to keep up with demand.

Quint-C needed a robust and scalable solution: an industrial coding system with the durability to handle harsh conditions and the precision to ensure compliance. The ideal replacement would be an industrial inkjet printer or industrial inkjet coder that could automate the marking process, reduce costs, and improve overall efficiency.

What Was Holding Back Effective Pallet Marking

Manual Processes: Outdated methods like stamping and heat branding slowed down production and drove up labor costs, making the pallet marking process inefficient and unsustainable.

Rough Conditions: The industrial environment—full of vibrations, sawdust, and splinters—created a tough setting where typical printers and marking tools struggled. Most equipment wasn’t built to survive the demands of a real-world industrial coding system.

Unclear Markings: Heat branding often produced uneven, hard-to-read markings that led to compliance issues. Without a reliable industrial inkjet coder, the company faced constant challenges ensuring consistent and legible codes on every pallet.

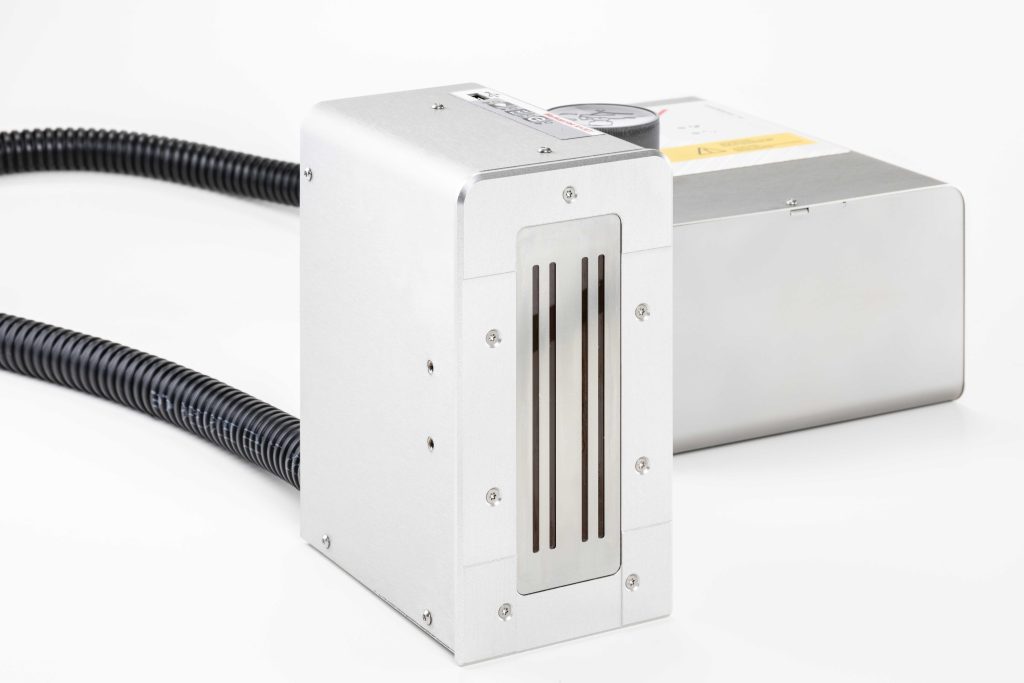

The Solution: Integra PP108 Inkjet Printer

To help Quint-C modernize their pallet marking process, the company called on Pak-Tec, a provider of end-of-line packaging solutions including labeling, marking, and coding technologies. Pak-Tec implemented equipment from AT Information Products, selecting the Markoprint Integra PP108 high-speed industrial inkjet printer built for tough production environments.

This upgrade replaced manual stamping and heat branding with fast, automated inkjet pallet marking, delivering clear, durable codes with minimal operator involvement. The Integra PP108 integrated seamlessly into existing machinery, transforming Quint-C’s production into a more efficient, accurate, and scalable industrial coding system—built to withstand dust, vibrations, and rugged shop floor conditions.

What Makes the Integra PP108 Stand Out Among Industrial Inkjet Printers

- Fast Printing: Prints clear, durable pallet markings at speeds up to 500 feet per minute—perfect for high-volume industrial coding systems.

- Sharp Resolution (960 DPI): Delivers bold, easy-to-read markings that meet IPPC and heat treatment compliance standards with exceptional clarity.

- Smart Ink Use: Advanced grayscale technology supports detailed graphics and logos while optimizing ink consumption, lowering operational costs.

- Tough Printhead: Designed to withstand dust, vibrations, and debris—ideal for rugged pallet shop environments where other industrial inkjet printers might fail.

- Quick Startup: Self-priming system ensures fast, hassle-free operation with minimal downtime.

- Compact & Strong: Space-saving design fits easily into existing pallet machinery and requires very little maintenance—perfect for continuous, reliable pallet marking.

The Results: Smarter Pallet Marking with Industrial Inkjet Coders

Implementing the Integra PP108 industrial inkjet printer transformed Quint-C’s outdated pallet marking process into a streamlined, cost-effective industrial coding system. The impact was immediate:

- 15% Faster Production: Eliminated delays caused by manual heat branding, allowing the line to move at full speed with automated inkjet coding.

- Lower Labor Costs: Automation reduced reliance on manual labor, freeing up employees for higher-value tasks.

- 80% Savings on Marking: Switching from heat branding to an industrial inkjet coder significantly cut material and maintenance expenses.

- Clear & Consistent Codes: Delivered high-resolution, compliant markings on every pallet—no smudges, rework, or downtime.

- $45,936 Annual Savings: Material, labor, and efficiency gains translated into substantial yearly cost reductions.

- 339.08% Annual ROI: The investment in the Integra PP108 quickly paid off by slashing costs and boosting output.

- 11.3-Month Payback Period: In less than a year, the new industrial inkjet printer paid for itself—making it a smart, scalable solution for long-term gains.

Reliable Partners in Industrial Printing

AT Information Products delivers strong, long-lasting industrial inkjet printer solutions tailored for harsh, high-demand environments like pallet manufacturing. With the help of trusted partner Pak-Tec, the Markoprint Integra PP108 was installed quickly—boosting production speed, marking accuracy, and cost-efficiency for Quint-C.

Why AT Information Products?

- Experts in high-speed industrial inkjet printing and coding systems

- Proven, rugged solutions for challenging industrial marking environments

- Seamless integration, fast setup, and dedicated support